Description

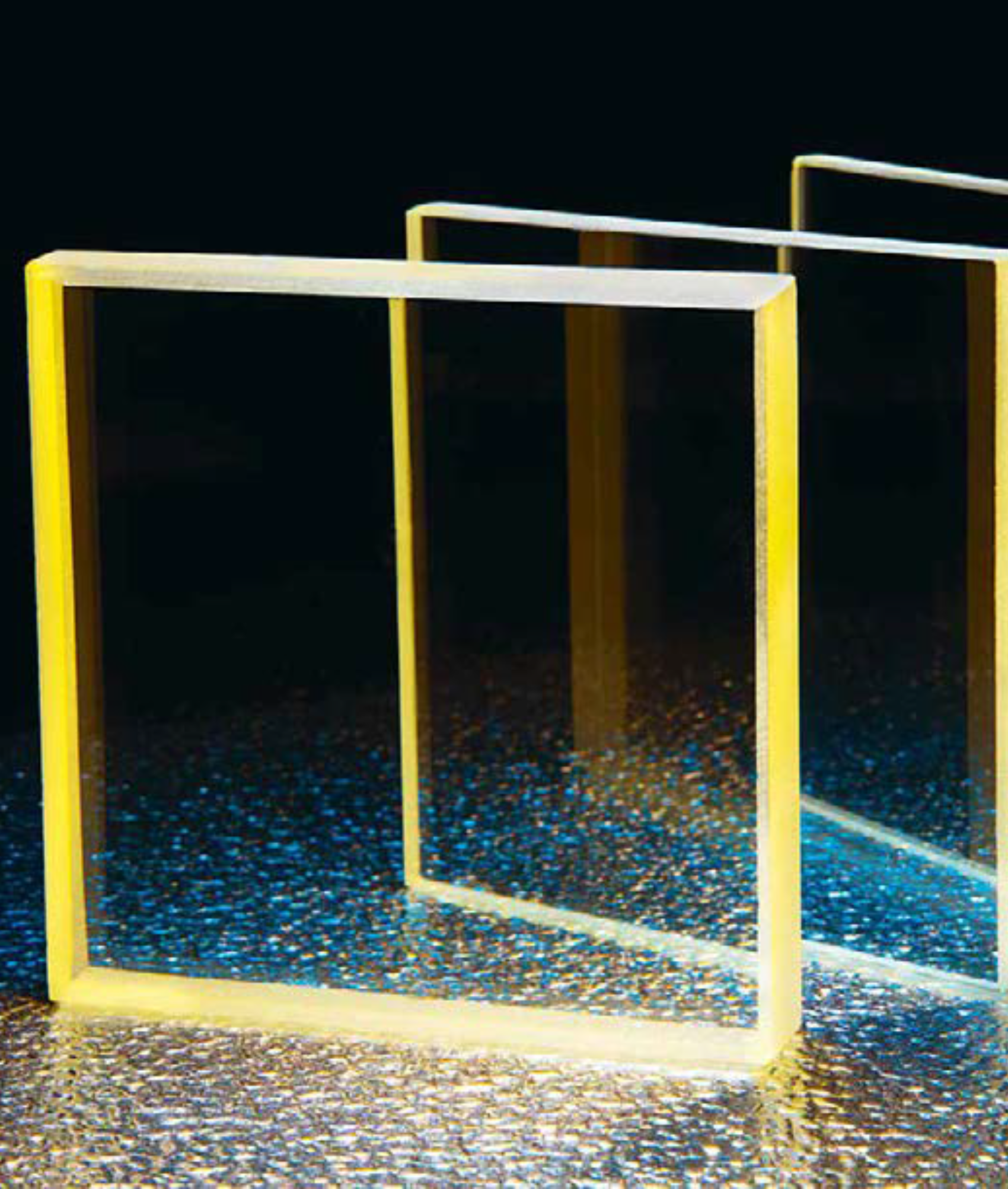

Constructed from prefabricated timber-framed panels wrapped in conductive copper foil, this system delivers strong RF attenuation in a lightweight, adaptable format. Each panel is carefully aligned and mechanically fixed on-site, forming a continuous shield with minimal construction complexity.

Designed with modularity in mind, the copper panels allow for quick and clean assembly, significantly reducing time on site compared to traditional copper construction. The system accommodates efficient magnet delivery and future equipment changeovers—wall or ceiling sections can be temporarily removed and reinstated without compromising the integrity of the overall shield. This capability minimizes disruption, streamlines

service logistics, and supports evolving imaging technology needs.

The flooring features copper foil laminated over a solid MDF base, with perimeter bonding for continuity and a protective overlay to preserve shielding performance during daily use. While copper foil systems are inherently more delicate than aluminum alternatives and offer slightly less acoustic insulation, they remain a viable and efficient choice for facilities prioritizing cost control, installation speed, and modular flexibility.

Modular Architecture for Real-World Demands

The true advantage of the Imaging Solutions system lies in its modularity. All wall and ceiling panels can be independently removed and reinstalled without compromising RF integrity.

Whether you’re planning for a future MRI upgrade, need to accommodate architectural changes, or simply require system

access—our modular aluminum design offers unmatched flexibility.

- Easy system expansion or reconfiguration

- Simple panel removal for magnet replacement or servicing

- Future upgrade-ready without invasive reconstruction

- No degradation of shielding integrity during changeovers

By contrast, traditional foil-based cages often require cutting, patching, and resealing—introducing long-term reliability concerns and unnecessary costs. Our mechanical joins eliminate these risks, ensuring long-term durability and low maintenance.

Rapid Installation. Minimal Downtime.

Our streamlined process enables fast, efficient project turnaround with minimal disruption, especially if being installed in an already operational radiology department or practice. Each cage is custom-fabricated off-site and shipped as a per-engineered kit to reduce time on-site and labor costs.

Typically 35m2 RF shield can be assembled within 10 working days, or 1-2 weeks. This condensed two-week window allows healthcare providers to accelerate their commissioning schedule and return to clinical operations sooner. Reduced construction disruption means higher uptime and faster ROI.

Custom-Tailored. Clinically Aligned.

No two MRI suites are the same—which is why our systems are never off-the-shelf. Each RF cage is designed in collaboration with your stakeholder team to align with existing infrastructure, services, and imaging workflows.

Our team can incorporate:

- RF windows, doors and waveguides

- Fit-out including wall, ceiling and flooring

- Electrical and lighting

- Cabinetry for filter cupboards or coils

- HVAC and utility access points

- Service panels, i.e medical gases

Future-Proof Investment.

Lower Lifetime Costs.

With imaging technology evolving rapidly, your RF shielding must adapt with it. Our modular aluminum systems are designed to minimize lifecycle costs through:

- Fast, non-destructive magnet change-outs

- Simplified service access

- Lower maintenance requirements

- Reduced upgrade labor costs

This translates into fewer downtimes, lower total cost of ownership, and long-term shielding performance that matches your evolving clinical needs.

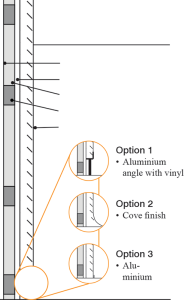

Interior Fit-Out Options include:

Quietspace® Panel

When there is no room for compromise, Quietspace® Panel is the best solution for superior sound absorption without it being obvious. Quietspace Panel has been engineered to absorb a minimum of 85% of the sound energy it meets. This means annoying and distracting noise no longer feels that way.

Intentionally designed in three of the most common interior colours; black, grey and white, Quietspace Panel can easily blend into ceilings and walls to simply do its job. But if you would like to turn your acoustics into a design element without losing the performance, simply use the ultimate upgrade; and combine with Autex Vertiface®.

Face your panels in any of our colours to create full feature walls or custom shapes and designs. Anything is possible. Available in 25mm, 50mm, 75mm and 100mm there’s no acoustic challenge Quietspace Panel can’t meet.

Acoustic Performance

Quietspace Panel is specifically designed to reduce and control reverberated (echo) noise in building interiors.

Minimum Noise Reduction Coefficient 0.85.

Installation

Install as per Autex recommendations. Install instructions are included in each pack or available on the website. If Quietspace Panel is to be specified for use other than as a wallcovering, please seek guidance from your Autex account manager.

Mars™ Healthcare ClimaPlus™ Ceiling Tiles

Mars™ Healthcare ClimaPlus™ acoustical panels have a water repellent membrane designed to be durable and deliver excellent noise reduction, sag resistance and high light reflectance.

Mars Healthcare exceeds JIS Z 2801 standard for antimicrobial performance. They are 3rd party certified and meet the requirement for PC1 and PC2 physical containment facilities.

Features and Benefits:

- High NRC (.75) for excellent sound control

- High light reflective finish (LR .90) reducing light fixtures and energy use

- Washable and soil-resistant finish

- Impact and scratch resistant

- Meets USDA/FSIS guidelines for use in food processing areas

- Achieves FDA standards for smoothness, durability and clean-ability

- ClimaPlus™ 30-year lifetime system warranty against visible sag, mould and mildew

- Low VOC emitting product meets ASTM D5116 Standard Practice for the testing of VOC emissions

Coil Cabinets

Imaging Solutions can design and build a coil cabinet to suit your requirements. We can custom design a cabinet from ground up if you have specific requirements or we can use the manufacturer of your MRI machine’s suggested layout. The cabinet can be made out of a range of materials to match the colour scheme or theme of your room.

Turn Key MRI Rooms

Australasia’s largest turn-key range of MRI RF cage design and construction related products and services.

Our single source supply platform includes construction, engineering, design, project management, planning, testing and accessories.

Site and Host Room Audit, Review and Planning

With builders, engineers, planners, and draftsmen at the ready, Imaging Solutions is your one-stop shop for new MRI room projects. Whether you’re opening a new imaging practice or adding MRI services to an existing facility, we provide the technical insight and project planning expertise to support you.

Project Management Team Development

From early-stage planning through to final handover, Imaging Solutions supports you every step of the way. Our experienced project management team can oversee the entire process, giving you peace of mind and a single point of accountability.

RF Shield Construction

Imaging Solutions offers a range of RF shielding solutions designed to meet a variety of project requirements and budgets. Our RF shield systems have been optimized for streamlined deployment, accelerating project timelines and minimizing disruption to surrounding environments. Whether part of a new build or retrofit, each system is engineered for fast, compliant, and efficient installation.

RF Cage Integrity Testing for Compliance when Initially Installed

Imaging Solutions has developed a highly advanced RF testing and reporting capability, using state-of-the-art, calibrated equipment. We conduct full-spectrum RF testing at all frequencies required by OEMs to verify performance against strict compliance standards. Every RF shield undergoes two comprehensive testing phases, starting with the initial cage installation.

Plant Equipment

Chillers, CRACs, ACs, and Installation and Commissioning

Imaging Solutions delivers fully integrated plant equipment solutions for MRI suites, including chillers, CRAC units, and air conditioning systems. Our expert team manages the complete process, from specification and supply to installation and commissioning, ensuring system compatibility, optimal performance, and seamless coordination within your build. By consolidating plant services through a single trusted provider, we simplify your project delivery and reduce the need for multiple contractors.

Internal Fit Out

Internal fit-out is a critical component of any MRI suite, delivering both acoustic performance and clinical functionality. Imaging Solutions offers a complete internal fit-out service, from flooring, walls, and ceilings to lighting, electrical, and integrated cabinetry.

Magnet Delivery

Imaging Solutions’ RF Shields are uniquely engineered to allow for efficient magnet delivery without permanent structural modification. This flexibility not only accelerates installation timelines but also ensures future changeouts or upgrades can be completed with minimal impact to shielding performance.

RF Cage Integrity Testing for Compliance following Magnet Delivery

A second round of RF testing is conducted after the magnet has been delivered and the RF cage re-sealed. This post-installation testing ensures that the shield remains fully compliant and has not been compromised during delivery. Detailed test reports and compliance certifications are issued at each stage, verifying that the shield meets, and often exceeds, MRI vendor requirements.

MRI Equipment and Accessories

Imaging Solutions offers a complete portfolio of MRI-compatible accessories from leading global brands. Our solutions include patient monitoring systems, injectors, and a full range of MRI safety equipment, allowing you to outfit your suite with proven, high-performance tools from a trusted single source.

Patient Relaxation

Our range of patient relaxation enhancements are designed to reduce stress, anxiety, and sensory discomfort during MRI procedures. These solutions can be used individually or in combination to create a welcoming, calming environment that enhances the overall experience for both patients and staff.

Project Handover

At project completion, an Imaging Solutions project manager will meet with all stakeholders on-site to conduct a formal handover. Together, we review the scope of works and confirm that all deliverables have been completed to the agreed specifications, ensuring full satisfaction before sign-off.