Description

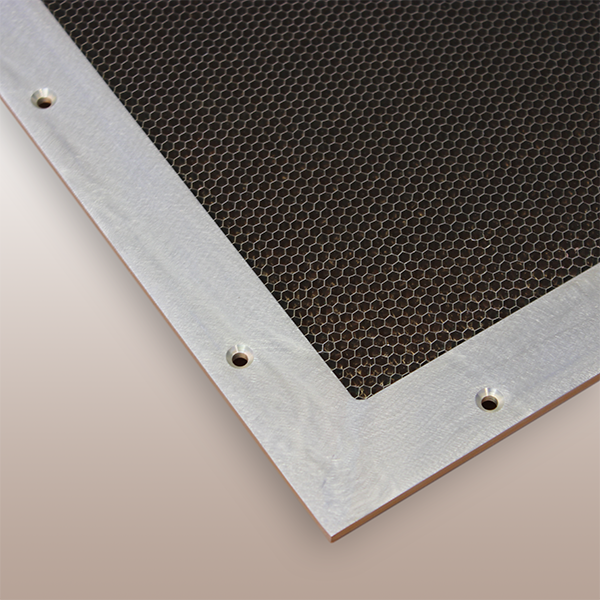

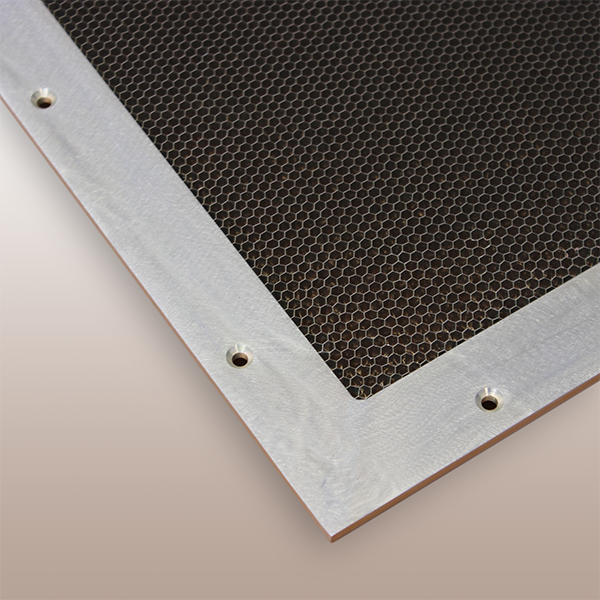

Assorted Waveguides

Both air-conditioning and pressure relief wave guides are constructed of two layers of high grade aluminium honeycomb material sealed into a support frame designed for mounting into RF cage panels ready for air conditioning duct adaption. These wave guides are positioned as required by the mechanical services contractor.

Filter / Pen Panels

These panels are dependent on the MRI vendor and are used to pass all interconnections between the magnet and the external environment. A special adaptor plate is mounted within the RF Cage lining to suit these individual panels supplied by the vendor.

Electrical Filters

Housed within the RF cage paneling these electrical filters are required to pass all auxiliary power and lighting to the internal workings of the cage. Especially designed to handle the current loading of these circuits these filters are required in pairs per electrical circuit.

Turn Key MRI Rooms

Australasia’s largest turn-key range of MRI RF cage design and construction related products and services.

Our single source supply platform includes construction, engineering, design, project management, planning, testing and accessories.

Site and Host Room Audit, Review and Planning

With builders, engineers, planners, and draftsmen at the ready, Imaging Solutions is your one-stop shop for new MRI room projects. Whether you’re opening a new imaging practice or adding MRI services to an existing facility, we provide the technical insight and project planning expertise to support you.

Project Management Team Development

From early-stage planning through to final handover, Imaging Solutions supports you every step of the way. Our experienced project management team can oversee the entire process, giving you peace of mind and a single point of accountability.

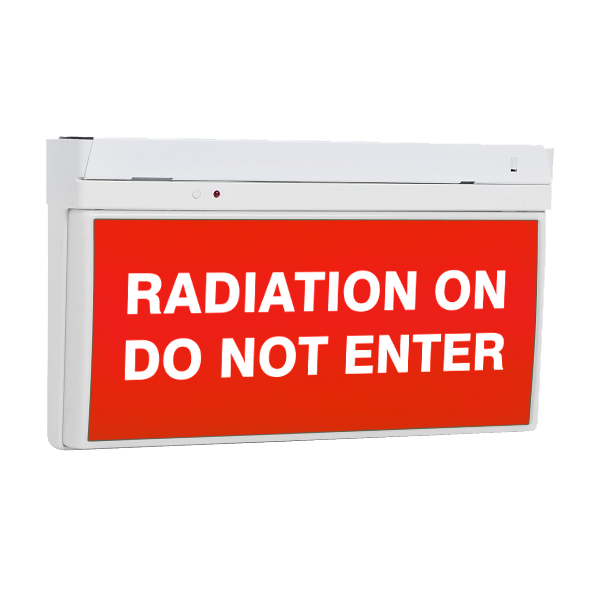

RF Shield Construction

Imaging Solutions offers a range of RF shielding solutions designed to meet a variety of project requirements and budgets. Our RF shield systems have been optimized for streamlined deployment, accelerating project timelines and minimizing disruption to surrounding environments. Whether part of a new build or retrofit, each system is engineered for fast, compliant, and efficient installation.

RF Cage Integrity Testing for Compliance when Initially Installed

Imaging Solutions has developed a highly advanced RF testing and reporting capability, using state-of-the-art, calibrated equipment. We conduct full-spectrum RF testing at all frequencies required by OEMs to verify performance against strict compliance standards. Every RF shield undergoes two comprehensive testing phases, starting with the initial cage installation.

Plant Equipment

Chillers, CRACs, ACs, and Installation and Commissioning

Imaging Solutions delivers fully integrated plant equipment solutions for MRI suites, including chillers, CRAC units, and air conditioning systems. Our expert team manages the complete process, from specification and supply to installation and commissioning, ensuring system compatibility, optimal performance, and seamless coordination within your build. By consolidating plant services through a single trusted provider, we simplify your project delivery and reduce the need for multiple contractors.

Internal Fit Out

Internal fit-out is a critical component of any MRI suite, delivering both acoustic performance and clinical functionality. Imaging Solutions offers a complete internal fit-out service, from flooring, walls, and ceilings to lighting, electrical, and integrated cabinetry.

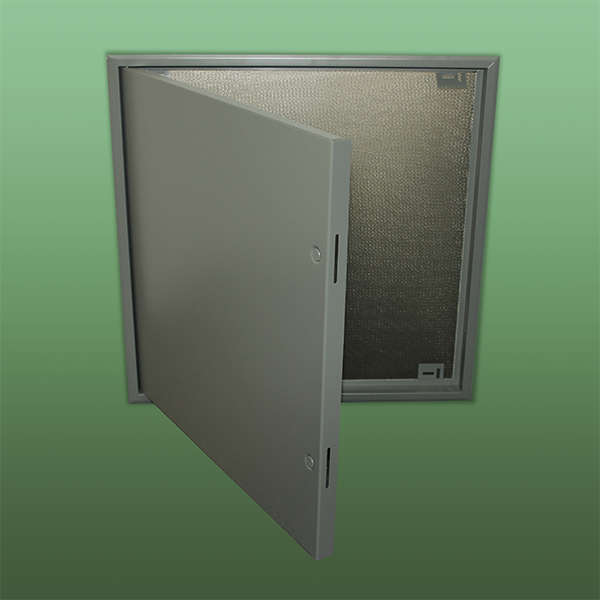

Magnet Delivery

Imaging Solutions’ RF Shields are uniquely engineered to allow for efficient magnet delivery without permanent structural modification. This flexibility not only accelerates installation timelines but also ensures future changeouts or upgrades can be completed with minimal impact to shielding performance.

RF Cage Integrity Testing for Compliance following Magnet Delivery

A second round of RF testing is conducted after the magnet has been delivered and the RF cage re-sealed. This post-installation testing ensures that the shield remains fully compliant and has not been compromised during delivery. Detailed test reports and compliance certifications are issued at each stage, verifying that the shield meets, and often exceeds, MRI vendor requirements.

MRI Equipment and Accessories

Imaging Solutions offers a complete portfolio of MRI-compatible accessories from leading global brands. Our solutions include patient monitoring systems, injectors, and a full range of MRI safety equipment, allowing you to outfit your suite with proven, high-performance tools from a trusted single source.

Patient Relaxation

Our range of patient relaxation enhancements are designed to reduce stress, anxiety, and sensory discomfort during MRI procedures. These solutions can be used individually or in combination to create a welcoming, calming environment that enhances the overall experience for both patients and staff.

Project Handover

At project completion, an Imaging Solutions project manager will meet with all stakeholders on-site to conduct a formal handover. Together, we review the scope of works and confirm that all deliverables have been completed to the agreed specifications, ensuring full satisfaction before sign-off.